GM 1998-2003 SUV/Car GT280 4P Fuel Pump Wiring Harness

$79.99

per EACH FPWH-023 - 97-03 GM SUV / Auto 280-Series Fuel Pump Wiring Harness

APPLICATIONS:

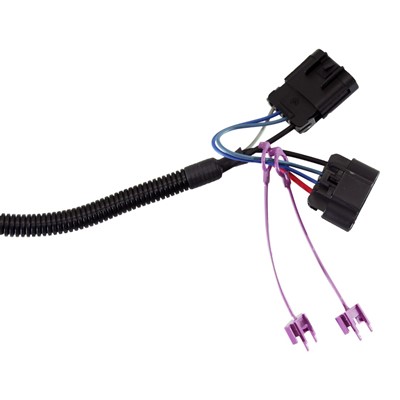

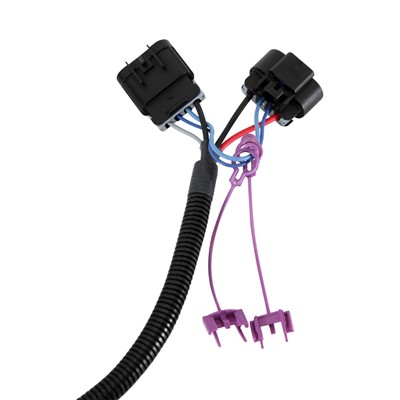

- 1997 to 2003 GM trucks and cars which have had their modules updated / replaced and their factory wiring updated / spliced from the 4-way Metri-Pack square connector to the new 280-series electrical connectors.*

- This harness is not compatible with L59 flex-fuel modules.

- This harness should not be used with 2008+ models which are equipped with an electronic fuel pump flow control module.

FEATURES:

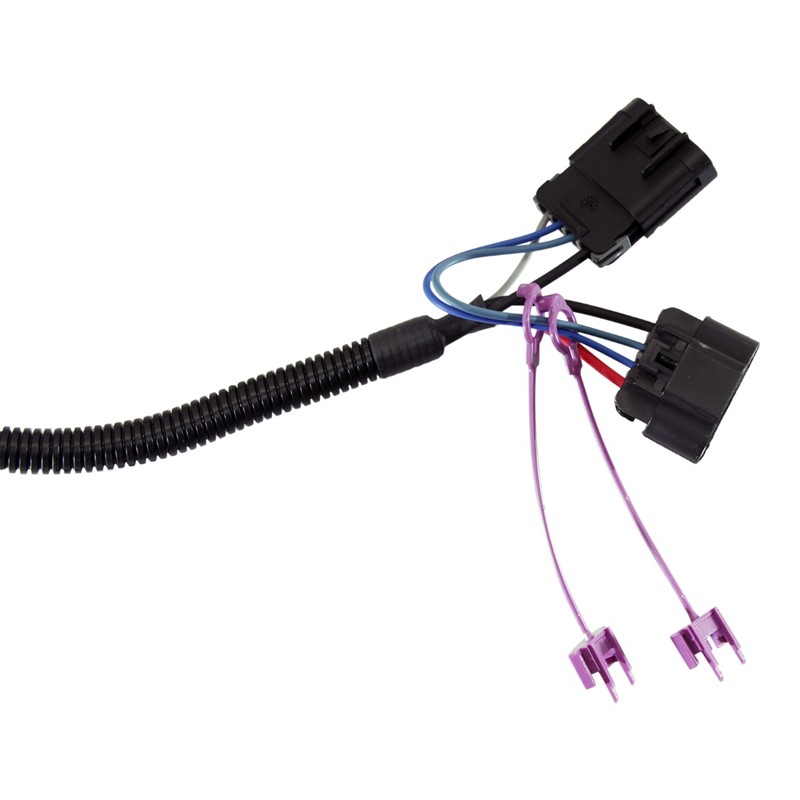

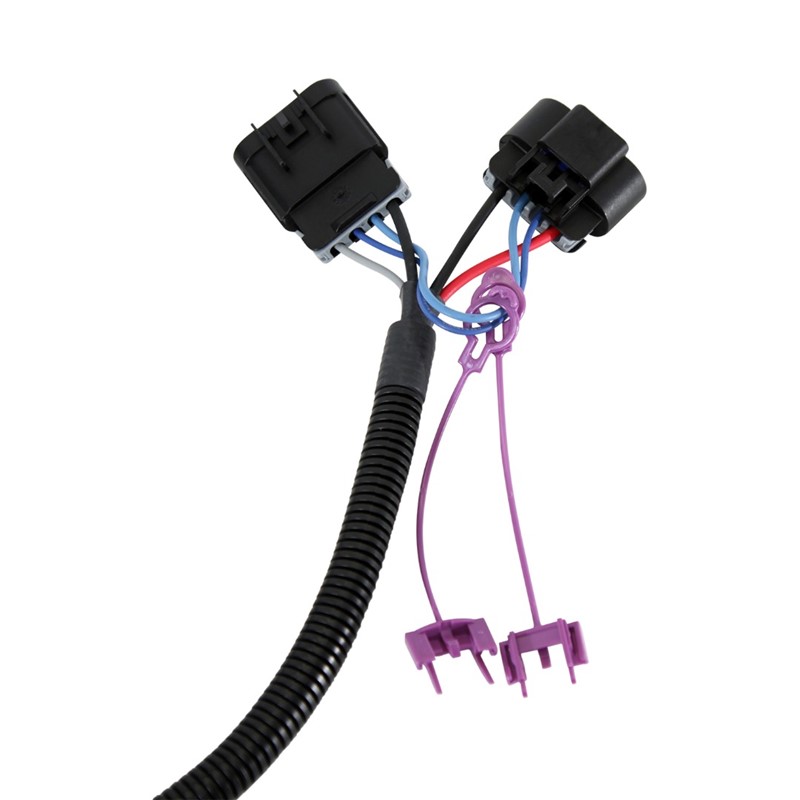

- Plug & Play (no cutting or splicing required)

- Weatherproof factory connectors

- Heavy-duty automotive-grade copper wire

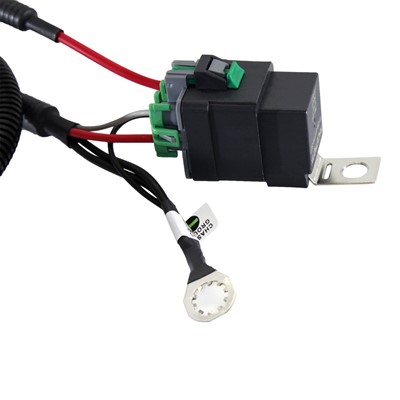

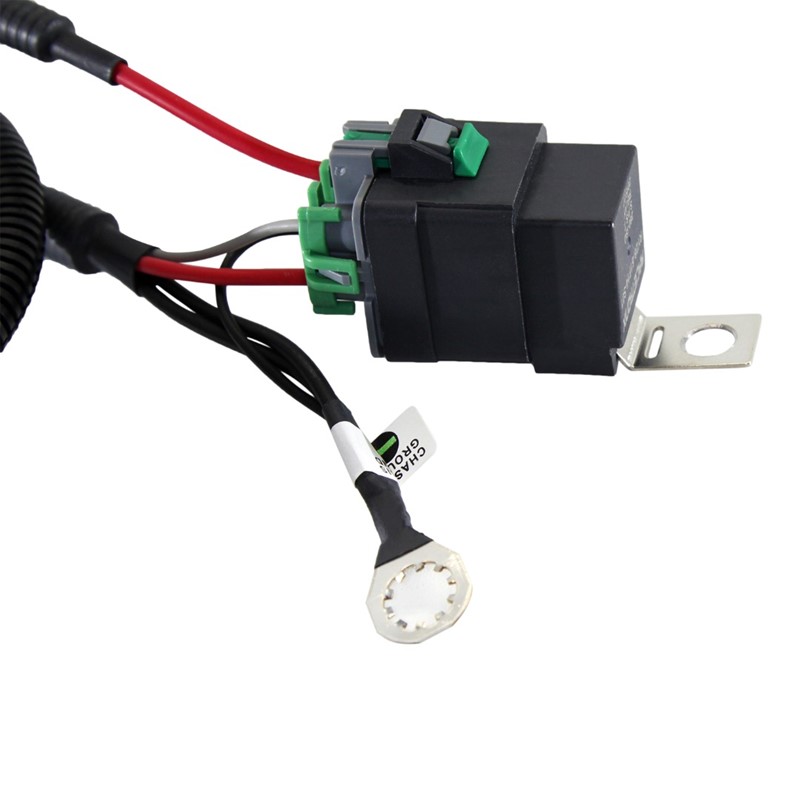

- Heavy-duty weatherproof relay

- Weatherproof fuse holder

- Alternator-direct power for maximum pump performance

- Silicon grease, spare fuse, wire ties included

- Stainless steel mounting hardware

- Compatible with various pump boosters (i.e. KB, MSD) (optional)

Why use a Racetronix Fuel Pump Upgrade Harness?

Alternator-direct power for maximum voltage / True Plug & Play with GM type connectors.

No cutting, splicing, crimping or soldering. Retain factory configuration. Just plug it in and you are done!

High performance fuel pumps need a good power source in order to perform to their full potential. On average a high-performance fuel pump requires 2-3 times as much power as a factory fuel pump. Factory wiring is just enough for a factory pump's power requirements because manufacturers need to save cost and weight. Racetronix field tests have shown that running a high-performance fuel pump off of the factory wiring can cut pump performance by 30% or more. Problems with failing factory relays, connectors/terminals and fuse contacts are also common when excessive load is placed on them.

The Racetronix plug and play harness is designed to remove all fuel pump load from the factory pump circuits while providing the pump with a new heavy-duty power source. The Racetronix harness gets its power directly from the alternator's battery terminal. The voltage at the alternators output is typically 1-2 volts higher than at the battery when the motor is running (high charge/load conditions and WOT). This means that your high-performance pump will provide 20% or more more fuel. The Racetronix harness uses high-quality automotive-grade wire which is resistant to oil, gas, heat and rot. The main length of wire in the Racetronix harness is heavy-gauge stranded copper which is three to four gauges thicker than factory wires. This helps reduce resistive power loss to almost non-existent levels. This helps improve pump performance by as much as another 10-20%. (Competitive harnesses typically use wire which is one gauge thinner than ours). High-quality weatherproof fuse holders and relays are used for maximum reliability. The Racetronix harness has factory-type weatherproof connectors which plug directly into your fuel pump module/sender so no cutting or splicing is required.

This harness is covered with Nylon loom (GM spec. GMP.PA6.003, -40ºF to 300ºF). Nylon loom is more flexible, slicker, shinier and has a higher temperature rating than the PE loom used by other vendors. Nylon loom provides superior protection and eases installation especially in colder climates.

Redundant grounds = improved voltage & reliability:

A redundant ground is provided which loops into the harness. This loop enhances the pump's ground providing a two-fold improvement.

Pump booster PnP ready:

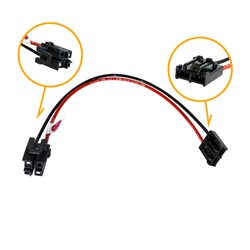

Many people who install supercharger, turbo or nitrous oxide systems will chose to use a fuel pump booster / voltage amplifier (KB BAP or MSD) which can increase pump performance upwards of 50%. Up until now people installing a booster would have to cut into the factory wiring harness which for many reasons is not a very good approach. This is no longer required with the Racetronix harness as it is equipped with an intermediate high-current (30 amp) connector just after the relay. This allows for easy plug & play addition of a pump voltage booster. The Racetronix harness removes the increased load off of the factory wiring created by the booster's amplification process. The Racetronix harness only supplies power to the pump booster when the vehicle computer commands fuel pump operation so there will be no parasitic load on your battery when engine is not running. The Racetronix harness allows the booster to be removed easily should the need arise. The booster is typically mounted close to the fuel tank underneath the vehicle where these is plenty of room, good ventilation and minimal exposure to the elements. The Racetronix harness further enhances the pump booster's performance by eliminating the factory wiring's voltage drop which would require more voltage amplification as compensation. The best part is that the Racetronix harness is so easy to install that the labor savings will usually pay for the harness itself when compared to hardwiring a solution from scratch.

Hardware included:

Plenty of wire ties are included as well as a stainless steel mounting hardware for the fuse holder, spare 20A ATC fuse and silicon grease to prevent corrosion and lubricate the chassis-mounted ground leads .

Racetronix harnesses are

considered the best by which all others are judged. Attention to detail

in every Racetronix harness is evident at first glance. Racetronix spares

no expense to ensure reliability, ease of installation and performance.

All Racetronix harnesses

are assembled using our computerized crimp-quality monitoring system and

then circuit checked for the utmost in reliability. This Racetronix harness is backed by our limited lifetime warranty.

UPGRADE OPTIONS

PBIC

The Racetronix harness comes

equipped with an interface connector just after the relay. This connector in combination with an optionally

supplied connector set allows for easy plug and play addition

of a pump booster / voltage amplifier (i.e. MSD, KB etc.). These voltage amplifiers / boosters will allow a single in-tank pump system to support an additional 100-250+ flywheel HP (B.S.F.C. dependant) when run at 16-17 volts. This configuration offloads the excessive current draw placed on the factory wiring onto the heavy gauge Racetronix harness system. System diagnosis becomes easier by simply being able to unplug, isolate and bypass sections of the wiring system.