C44 Corvette 1989-1996 Fuel Pump Wiring Harness*

$79.99

per EACH FPWH-014 - 1989-1996 C4 Corvette

APPLICATIONS:

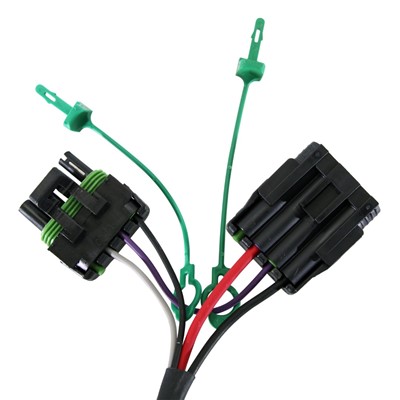

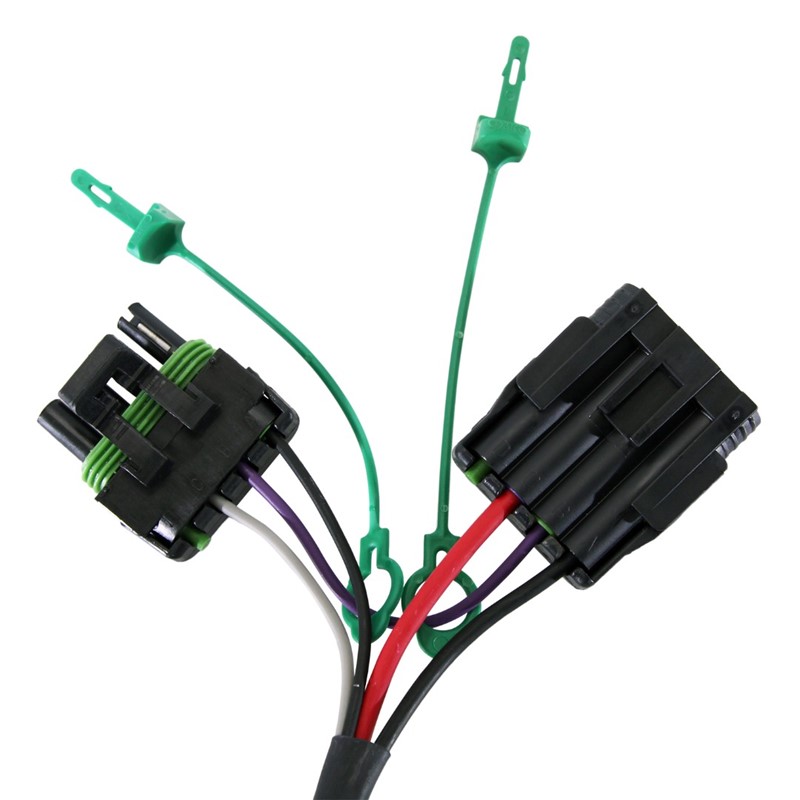

- Plug & Play (no cutting or splicing required)

- Weatherproof factory connectors

- Heavy 10 gauge automotive-grade copper wire

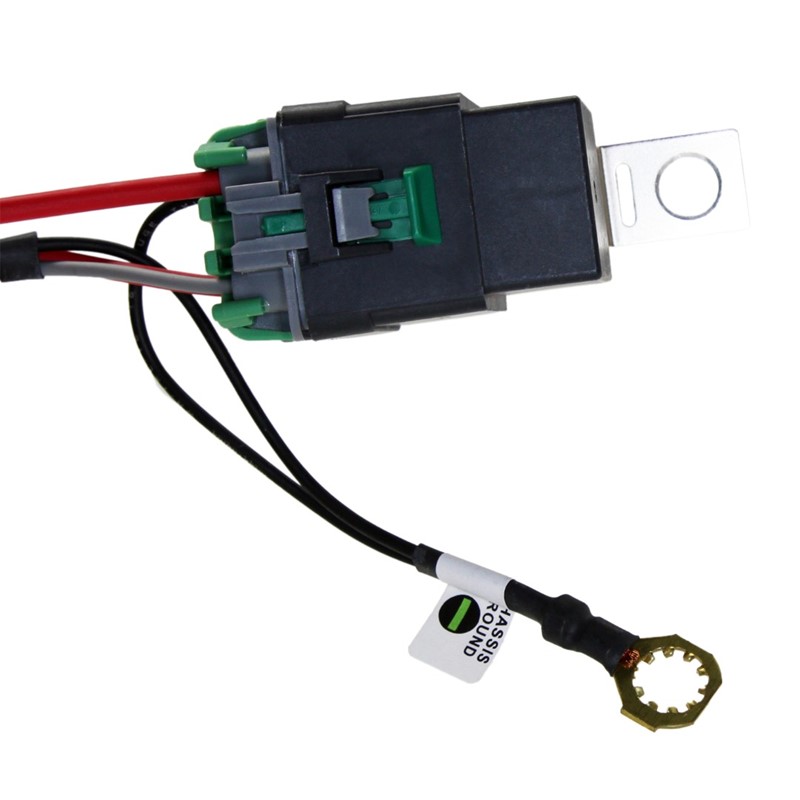

- Heavy-duty 40 amp weatherproof relay

- Weatherproof fuse holder

- Alternator-direct power for maximum pump performance

- Silicon grease, spare fuse, wire ties included

- Stainless steel mounting hardware

- Body ground upgrade with battery nuts (optional)

- Compatible with various pump boosters (i.e. KB, MSD) (optional)

As experienced drivers we all know from observation that there are certain electrical items on our car that when turned on cause the lights to dim, blower motors to slow down and the voltage meter reading on the dash to drop. There are various things that cause this such as battery condition and alternator output but for the most part it is factory wire resistance. In an ideal world car manufacturers would use heavier gauges of wire to reduce resistance in order to prevent voltage drop but that would add much cost, weight and bulk to the harnesses. As a tradeoff car manufacturers try to find a happy medium to satisfy the load requirements for a given circuit in the car without negatively impacting the operation of the device requiring the power at the end of the circuit. The C4's factory fuel pump power circuit was designed to provide power for the light current demands of a factory pump. Typically this circuit is comprised of 16 gauge wiring. Current demands can more than double when a high-performance fuel pump is installed. If we take a step back to high school physics, Ohm's law tells us that when we double the current flowing through a circuit with a fixed resistance the voltage loss across that circuit doubles. The power loss is quadrupled across this circuit which is given off as heat (wasted energy) which can cause electrical contacts (connectors / relays) to heat up and eventually fail. Starving a pump for voltage will cause it to slow down which escalates current demands even more thereby compounding the problem. For those who did not take physics we can consider this scenario... We all know someone who has a high-power car stereo system with heavy power cables running to the amplifier or someone with off-road driving lights using a dedicated circuit with relays. We know what would happen if these amplifiers and lights were hooked up to the same factory circuits which supply the the factory stereo or headlamps! So we pose the question 'how is a high-performance fuel pump any different?' Installing an external fuel pump requires a dedicated power circuit. Just because the factory wiring to your pump is convenient think twice about cramming a 20 amp fuse in panel and consider what you are doing!

The

harness:

The factory circuit which supplies the pump is much longer and more complex than many people realize. The circuit looks something like this. Pump connector > in-tank bulkhead connector > external tank connector > relay > fuse box > steering column ignition switch > fusible link > starter solenoid > battery > alternator. Some of these circuits which the fuel pump sources its power from are shared which can compound the voltage drop problems.

The Racetronix harness bypasses the entire factory circuit path to provide maximum voltage at all times to your pump. The Racetronix harness uses heavy 10 gauge copper wire to reduce voltage-drop to very low levels so as not to impact pump performance. Our power feed comes off the back of the alternator where voltage is highest. The voltage at the alternator's output is typically 0.5-1.5 volts higher than at the battery voltage depending on the charge current. It then runs through a weatherproof fuse holder and then to the back of the car. The Racetronix harness has connectors which plug inline with the factory harness at the back of the tank. No cutting or splicing is required. High-quality weatherproof fuse holders and relays are used for maximum reliability. The Racetronix harness has a redundant ground upgrade as it is necessary to improve the harness on the negative side of the pump's supply as well. The only function the factory harness serves is to trigger the relay in the Racetronix harness (0.1 amps) and to supply the level sender signal to your dashboard fuel gauge. If the need should arise the Racetronix harness can be unplugged in a matter of minutes. Some people even use this feature to disable the vehicle and prevent theft by C4 savvy joy riders. All current series II Racetronix harnesses are equipped with a 30 amp intermediate power connector just after the relay. This connector allows any aftermarket pump booster (MSD / KB / BW) to simply plug into the Racetronix harness. Adding a pump booster (voltage amplifier) can increase pump output volume by as much as 35-40% when run at apx. 16.5 volts (pressure dependent). An extra connector set is included to be installed on the pump booster's power leads making it a plug & play interface.

Racetronix harnesses are

considered the best by which all others are judged. Attention to detail

in every Racetronix harness is evident at first glance. Racetronix spares

no expense to ensure reliability, ease of installation and performance.

All Racetronix harnesses

are assembled using our computerized crimp-quality monitoring system and

then circuit checked for the utmost in reliability. This Racetronix harness is backed by our limited lifetime warranty.

UPGRADE

OPTIONS

BGK

An optional battery to body

ground upgrade kit is available (P/N BGK8). This kit upgrades the under-rated

factory ground wire running from the battery to the chassis. It includes

an 8 gauge copper wire fitted with terminals and battery nuts with accessory

taps. We highly recommend this inexpensive option because this is a weak

point in these cars.

PBIC

The Racetronix harness comes

equipped with an interface connector just after the relay (see

product picture above). This connector in combination with an optionally

supplied connector set (P/N PBIC) allows for easy plug and play addition

of a pump booster / voltage amplifier such as the MSD or KB units. These voltage amplifiers / boosters will allow the Racetronix single in-tank pump system to support an additional 100-200 flywheel HP (B.S.F.C. dependant) when run at 16-17 volts. This configuration

offloads the excessive current draw placed on the factory wiring onto the

heavy gauge Racetronix harness system. System diagnosis becomes easier

by simply being able to unplug, isolate and bypass sections of the wiring

system.