Typhoon Fuel Pump Kit (RXP255E)

RFPK-013 - Typhoon / Jimmy / Blazer HP Fuel Pump Kit

The RFPK-013 is recommended for factory HP upgrades to 600FWHP @ 43.5PSI using the factory lines and fuel pressure regulator. Please factor in a 20-25% safety margin between what your motor needs and what your fuel system can supply.

Please contact your local Racetronix dealer to discuss your fuel requirements

* This kit was engineered for use with the factory Delphi hanger 25028845 / HP10004. We cannot guarantee compatibility with aftermarket hangers. Please submit your VIN number via our contact us form if you are not 100% sure of your application. No returns on open-box pumps.

| MAKE | MODEL | YEARS |

| CHEVROLET | S10 BLAZER | 1992-1994 |

| GMC | JIMMY | 1992-1994 |

| GMC | TYPHOON | 1992-1993 |

| OLDSMOBILE | BRAVADA | 1992-1994 |

Racetronix Fuel Pump Assembly

- Racetronix RXP255 255LPH turbine fuel pump with reduced noise and enhanced reliability with ethanol- enhanced fuels

- Filter sock - 30 micron filtering

- In-tank wiring harness / adapter

- High pressure fuel line

- Stainless gear clamps

- Pump mount grommet

- Pump sound insulation sleeve

- OE-Style molded tank gasket

- Pump test lead

The RXP255 pump uses new turbine technology to reduce pump noise, improve reliability and provide enhanced compatibility with Ethanol enhanced fuels.

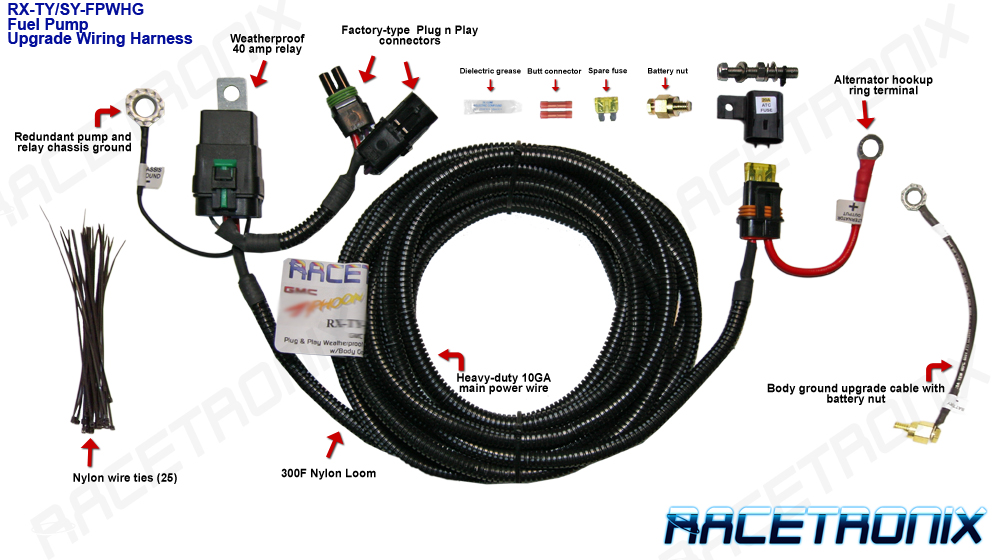

Racetronix Fuel Pump Upgrade Harness

- Plug & Play (no cutting or splicing required)

- Weatherproof factory connectors

- Heavy 10 gauge automotive-grade copper wire

- Heavy-duty weatherproof relay

- Weatherproof fuse holder

- Alternator-direct power for maximum pump performance

- Silicon grease, spare fuse, wire ties included

- Stainless steel mounting hardware

- Body ground upgrade with battery nuts

The Wiring Harness aka 'Hotwire harness'

No cutting, splicing, crimping or soldering. Retain factory configuration. Just plug it in and you are done!

High performance fuel pumps need a good power source in order to perform to their full potential. On average a high-performance fuel pump requires twice as much power as a factory fuel pump. Factory wiring is just enough for a factory pumps power requirements because manufacturers need to save cost and weight. Racetronix field tests have shown that running a high-performance fuel pump off of the factory wiring can cut pump performance by 30% or more. Problems with failing factory relays, connectors/terminals and fuse contacts are also common when excessive load is placed on them.

The Racetronix plug and play harness is designed to remove all fuel pump load from the factory pump circuits while providing the pump with a new heavy-duty power source. The Racetronix harness gets its power directly from the alternator's battery terminal. The voltage at the alternators output is typically 1-2 volts higher than at the battery when the motor is running (high charge/load conditions and WOT). This means that your high-performance pump can provide as much as 20% more fuel in some cases. The Racetronix harness uses high-quality automotive-grade wire which is resistant to oil, gas, heat and rot. The main length of wire in the Racetronix harness is ten-gauge stranded copper. This is three to four gauges thicker than factory wire which helps reduce resistive power loss to almost non-existent levels. This helps improve pump performance by as much as another 10-20%. (Competitive harnesses typically use wire which is one gauge thinner than ours). High-quality weatherproof fuse holders and relays are used for maximum reliability. The Racetronix harness has factory-type weatherproof connectors which plug directly into your fuel pump module/sender so no cutting or splicing is required.

UNIQUE FEATURES:

The Racetronix harness is covered with Nylon loom (GM spec. GMP.PA6.003, -40ºF to 300ºF). Nylon loom is more flexible, slicker, shinier and has a higher temperature rating than the PE loom used by other vendors. Nylon loom provides superior protection and eases installation especially in colder climates.

POWER

FEED:

Our

power feed comes off the back of the alternator where voltage is highest. It then runs through a weatherproof fuse holder which is mounted on the

back of the alternator with a supplied stainless steel bolt. The TR has

an unused hole in the back of the alternator which facilitates this fuse

holder mounting quite nicely. This location keeps the fuse holder out of

sight and the unfused wire down to a short 4 inches. Our

competition's fuse holder must be remote-mounted requiring self tapping

screws / holes. The unfused section of wire extends to the firewall.

Racetronix supplies a spare 20A ATM fuse, 25 black vinyl wire ties, silicon grease and mounting hardware with each kit.

Racetronix harnesses are

considered the best by which all others are judged. Attention to detail

in every Racetronix harness is evident at first glance. Racetronix spares

no expense to ensure reliability, ease of installation and performance.

All Racetronix harnesses

are assembled using our computerized crimp-quality monitoring system and

then circuit checked for the utmost in reliability. This Racetronix harness is backed by our limited lifetime warranty.

BGK

Some

people make the mistake of assuming the thick black wire coming from the

battery is a body ground. It is not. It is the motor ground and the motor

sits on rubber mounts. Due to the age of the vehicle we have seen some body

grounds so bad that the lights flicker on the car when in motion. To address

this problem Racetronix is offering a battery to body ground upgrade kit. This kit upgrades the thin ground wire running from the

battery to the inner side of the passenger's fender wall. It includes

an 8 gauge copper wire fitted with terminals and battery nuts with accessory

taps.. One end attaches to BATTERY - and the other to BODY GROUND. No modifications

to the factory battery terminals or boots are required. The new battery

nuts have a bolt on top that allows connections to easily be made to the

battery. Simply pop the old factory battery nuts out by pushing them out

from behind and pop the new ones in. They even look good too. > BLING :)

<