DIY Dual Pump Kit, 97-02

DIYDPK-C5 - 1997-2002 C5/C6 Corvette DIY PnP Dual Pump Kit

- For HP upgrades from 600-1400HP

- Twin Racetronix 255LPH or 340LPH turbine fuel pumps with reduced noise and 100% compatibility with E-85 fuel

- Billet dual pump coupler with Viton o-rings

- Teflon 10 gauge PnP dual in-tank harness - E85 Compatible

- High-pressure non-kinking fuel tube

- Intermediate PnP Harness - 10 gauge wire

- Dual PnP power harness - 10 gauge wire

The DIYDPK-C56 is recommended for factory HP upgrades from 650-1000/1400HP (gas). HP support will vary based on many factors such as fuel pressure, pump voltage, fuel line type/size, motor BSFC etc. Racetronix recommends a 20%+ safety margin for fuel delivery.

This kit is designed to fit in all C5 Corvettes manufactured before November 25, 2002 with VIN # 114931 (last six digits) or lower.

IF YOU ARE UNSURE OF YOUR MODULE NUMBER PLEASE E-MAIL US YOUR VIN # BEFORE YOU ORDER. WE CANNOT ALLOW RETURNS ON ANY OPEN BOX PUMPS PERIOD!

DIYDPK-C56 KIT

DPA-510E / DPA-680E Dual Pump Assemblies

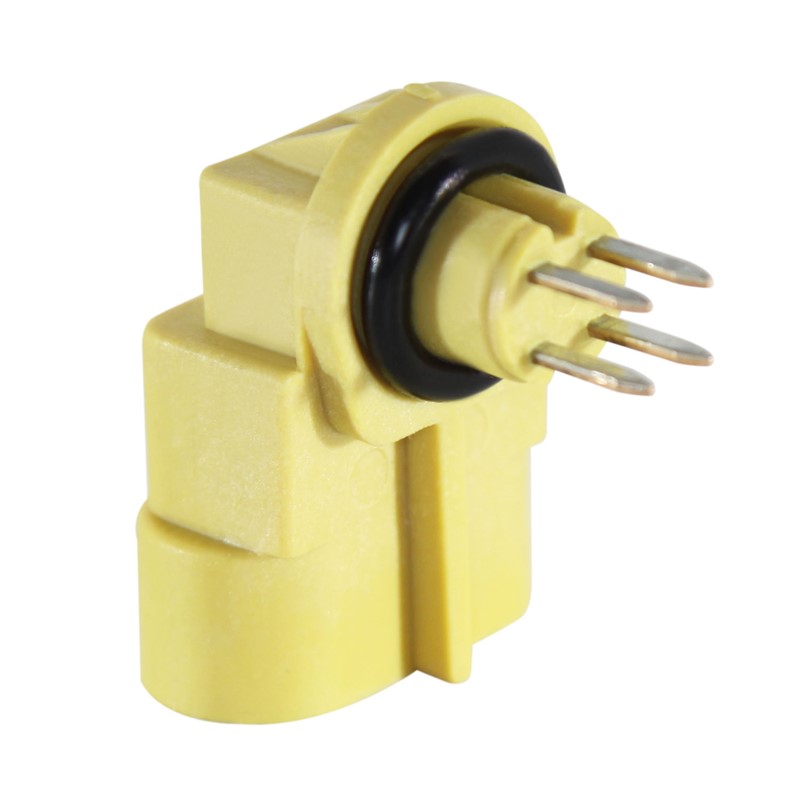

For customers who need enough fuel to support upwards of 1,000HP, Racetronix offers the DPA-510E dual in-tank fuel pump assembly with twin RXP255 255LPH fuel pumps (typical flow 550LPH+). An optional DPA-680E with two Racetronix RXP340 340LPH pumps is available to support upwards of 1400HP (typical flow 750LPH+). These dual pump assemblies are coupled using our billet dual pump coupler and stainless mounting bracket. The outlet uses 3/8" hose barb that can accommodate both rubber and plastic fuel lines. The billet coupler is fitted with Viton o-rings for a reliable push-fit seal. All components in this assembly simply slip together for simple assembly/disassembly. No clamps are required.

Racetronix Quality Pumps

The Racetronix DPA-510E/DPA-680E is based on Racetronix turbine pump technology which provides quiet reliable operation.

Wiring Harness Components

Racetronix wiring solution is made up of three components:

The main power harness maximizes performance and eliminates the potential for factory wiring failures. This is achieved by using 10-gauge TXL wire which is many times heavier than factory, along with quality weather-proof Delphi connectors and Racetronix sealed relays. Each circuit is independent with its own fuse, relay and ground control loop connectors. This harness provides these functions:

- Provides alternator/battery direct power to the rear of the vehicle which eliminates all voltage loss to the pumps and maximizes pump performance.

- It provides two independently fused circuits for proper pump protection and fire prevention.

- It provides two ground control connectors with jumpers allowing user-selectable primary/secondary pump control via the supplied pressure switch or optional (user supplied) control interface (i.e. PCM).

The intermediate harness is used to interface the main power harness, factory chassis harness and fuel module together. This harness provides these functions:

- It allows the fuel level sensor signal to pass from the fuel module through to the PCM.

- It diverts the fuel pump power signal to trigger the relays on the main power harness

- It passes power for the pumps from the main harness into the fuel module's proprietary bulkhead connector.

- It provides a redundant heavy-duty ground for the dual pump assembly.

The in-tank harness features custom Racetronix HD fine-strand Teflon wire which is E85 compatible. The in-tank harness provides these functions:

- It passes power from the fuel module's proprietary bulkhead connector to the fuel pumps

- It provides a connection to the fuel level sensor

- It provides a connection for the module's static grounding system.

The HIH-xxx harness connects the pressure switch to either of the control connectors on the main power harness using PnP weather-proof connectors.

Racetronix HPS heavy-duty industrial pressure switches are water tight and compatible with most solvents / fuels.

Every part of this wiring system is designed to provide maximum performance by maintaining 10-gauge wire from the alternator/battery straight through to the module (where possible) while being entirely weatherproof and plug & play.

FAQ (PRELIMINARY - DATA CURRENTLY BEING ADDED)

Q1. Which DPA assembly do I need 510 or 680 models?

A1. There are many factors which impact the choice of pump assembly required such as maximum WOT fuel pressure, motor BSFC, target A/F, fuel type etc. This is a very involved topic which is beyond the scope of this faq. There are many on-line articles which cover this technically topic in detail. Please review our RXP255 flow graph and RXP340 flow graph for reference. As a rule we recommend our DPA-510E for applications up to 1000FWHP and our DPA-680E for applications above 1000FWHP (using gas). These are the conservative specs of the DPA-680E installed in a module:

680LPH @ 43.5psi @ 13.5v @ 22.5A

820LPH @ 43.5psi @ 16.0v @ 27.5A

635LPH @ 58.0psi @ 13.5v @ 24.5A

790LPH @ 58.0psi @ 16.0v @ 29.5A

550LPH @ 80.0psi @ 13.5v @ 28.0A

710LPH @ 80.0psi @ 16.0v @ 32.5A

Q2. Which pressure switch do I need?

A2. We recommend that the pressure switch be chosen so that the secondary pump turns on approximately 100HP before the primary pump is maxed out. On forced induction cars this typically occurs around 600FWHP for the DPA-510E and around 750FWHP for the DPA-680E. Turning the secondary pump on too early will cause a pressure spike and engine over fueling / bog. Turning the secondary pump on too late will cause a lean condition, detonation and engine damage. Bigger is not always better because excessive flow will heat the fuel and draw more power. Always size your pump combination properly. The 4PSI (DPA-510E) and 7PSI (DPA-680E) switches are the most common for V8 engines.

Q3. Do I need to upgrade fuel lines?

A3. The factory fuel lines in the C5/C6 Corvette are good to a point. The biggest problem for high-HP applications is the regulator being located inside the fuel module. While this is good for reducing production costs and emissions it is not for stable fuel pressure at the motor. This is because the regulator has no way to compensate for feed-system pressure drop. We typically recommend adding a front mount regulator and -6 Teflon return hose for all applications that require a dual pump system. This will also reduce the required injector size (ease tuning) assuming the fuel pressure is boost referenced. This will help maintain a constant pressure differential across the injector.

Q4. How do I prepare my fuel system for a front-mounted regulator?

A4. Please see our FLK-C5 fuel rail + line kit for details.

Above 1000HP (800RWHP) we recommend a -8 Teflon hose to replace the factory feed line as well as upgraded rails for better fuel distribution. Proper fittings and Push-loc adapters are required. Please see our FLK-C5 fuel rail + line kit for details.

Q5. Does this kit maintain the jet-pump / venturi functionality of the factory fuel pump module?

A5. Not it does not. The pump assembly displaces too much volume in the factory module to be effective and therefore access ports must be made to ensure proper fuel reaches the high-flow pumps. This requires that a reasonable level of fuel must be maintained to prevent fuel starvation under hard acceleration and cornering..

MORE TO COME SOON