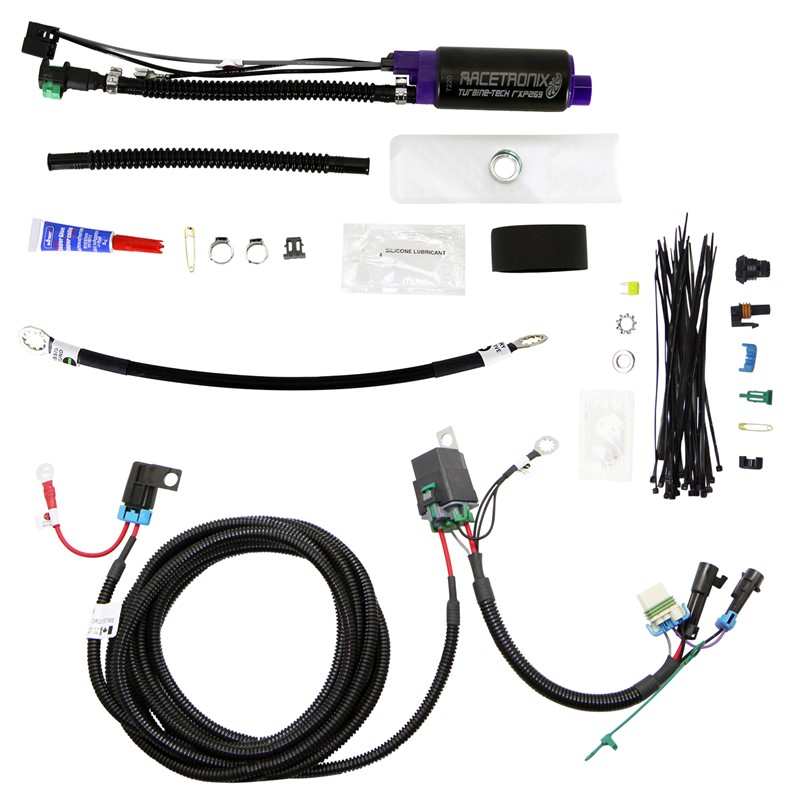

FLT1 Fuel Pump Kit HP 1993-97 (RXP255)

SEE NEW UPGRADED REPLACEMENT RFPK-033-255E

RFPK-003 - LT1 Camaro / Firebird / Trans AM 1993-1997

- Racetronix RXP 255L/Hr high-performance turbine fuel pump suitable for normally aspirated and forced induction motors

- Racetronix custom Walbro-GM Teflon in-tank harness

- High-pressure non-kinking 'Flex' fuel tube

- New Push-Lock fitting

- Custom 30-micron high-flow fuel sock

- Assembly adhesive & lubricant included

Why use a Racetronix Fuel Pump Assembly?

THE PUMP

The FPA-003A incorporates our new RXP Turbine-Tech fuel pump which supplies 255LPH of fuel @ 43.5PSI @ 13.5V. Racetronix RXP pumps use new turbine technology to reduce pump noise, improve reliability and provide enhanced compatibility with Ethanol enhanced fuels. This pump and harness combination will typically support 600 flywheel horsepower using factory lines. This HP number may be less with forced induction applications which require richer air/fuel mixtures and higher fuel pressure. Please factor in a 20-25% safety margin between what your motor needs and what your fuel system can supply.

APPLICATION-SPECIFIC FEATURES

The LT1 F-body cars have a pump that is inside a plastic fill-bucket. The fill-bucket's inlet and check-valve system in combination with the fuel pump are designed to draw fuel from the bottom of the tank via suction. This keeps the bucket full at all times and the pump fully immersed in fuel regardless of the tank level so that when the tank is low on gas and you are doing some hard cornering or acceleration the pump does not run dry and start aerating (air bubbles) the fuel. This happens as the fuel sloshes from side to side in the tank leaving the center low on fuel. The F-LT1 cars have minimal to no baffling in them. This can cause detonation and possible engine damage. The bucket also allows the car to operate with lower fuel levels in the tank due to its scavenging effect. The bucket can also effect motor cranking time as the priming time is reduced under certain conditions. The return line from the fuel pressure regulator is diverted back into the bucket via a filter sock inside so that the unused fuel also helps keep the bucket full at all times. Keeping the pump constantly immersed in gas within the bucket can extend the pump's life by not allowing it to be exposed to open air. Open air within the tank contains moisture and in time will cause the pump to rust / seize up especially if left to sit for long periods of time without the tank topped-up (i.e. winter storage). The Racetronix pump assembly is modified so that it will seal in the buckets rubber check-valve so that its function is retained. The Racetronix pump assembly is fitted with a factory style fuel tube not a rubber hose. This hose is important as when the fuel module is placed back in the tank it must pivot which can cause the rubber hose to kink. This fuel tube is much more resistant to the solvents in today's gas and it will not crack, split, swell and collapse like a rubber hose. The standard Walbro kit comes with a short length of rated rubber hose. The Racetronix fuel module is equipped with a one-piece wiring harness made from 14 gauge Teflon wire. (upgraded from the factory's 16 gauge harness) This is the same type of wire used at the factory as Teflon is the most resistant to deterioration when exposed to gas. This harness has a pump connector at one end and GM pins at the other which fit directly inside the factory connector. Due to the age of the F-LT1 cars much of the in-tank connectors are black / corroded due to age. The Racetronix harness replaces all these questionable components. The standard Walbro kit comes with a plastic coated in-line wiring adapter. This adapter must plug into the existing questionable factory in-tank wiring thereby adding additional connections and length.

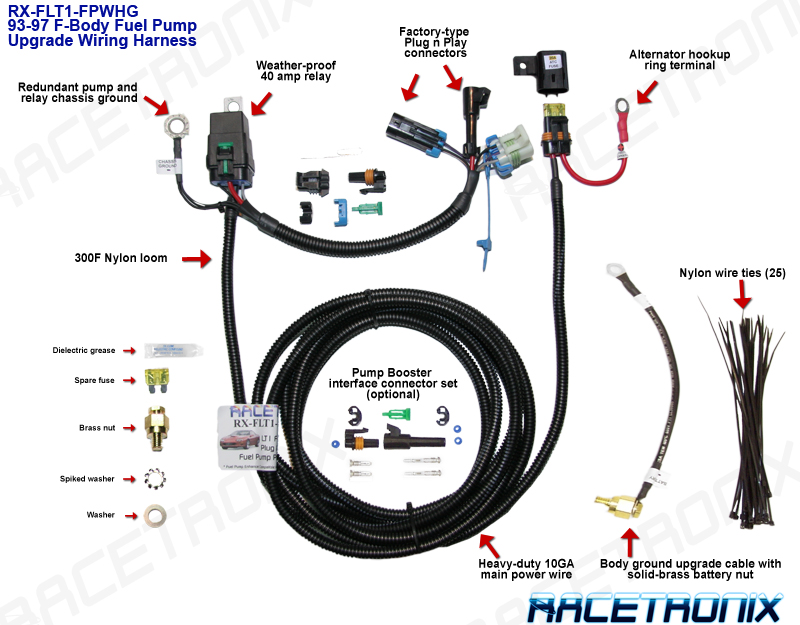

Why use a Racetronix Fuel Pump Upgrade Harness?

- Compatible with factory terminals and connectors (no cutting or splicing required)

- Weatherproof factory connectors

- Heavy-gauge automotive-grade copper wire

- Heavy-duty weatherproof relay

- Weatherproof fuse holder

- Alternator-direct power for maximum pump performance

- Silicon grease, spare fuse, wire ties included

- Stainless steel mounting hardware

- Body ground upgrade with battery nuts (optional *)

- Compatible with pump boosters (i.e. KB, MSD) (optional *)

RACETRONIX WIRING HARNESS

High performance fuel pumps need a good power source in order to perform to their full potential. On average a Walbro high-performance fuel pump requires twice as much power as a factory fuel pump. Factory wiring is just enough for a factory pumps power requirements because manufacturers need to save cost and weight. Racetronix field tests have shown that running a high-performance fuel pump off of the factory wiring can cut pump performance by 30% or more. Problems with failing factory relays, connectors/terminals and fuse contacts are also common when excessive load is placed on them.

The Racetronix plug and play harness is designed to remove all fuel pump load from the factory pump circuits while providing the pump with a new heavy-duty power source. The Racetronix harness gets its power directly from the alternator's battery terminal. The voltage at the alternators output is typically 1-2 volts higher than at the battery when the motor is running (high charge/load conditions and WOT). This means that your Walbro high-performance pump can provide as much as 20% more fuel in some cases. The Racetronix harness uses high-quality automotive-grade wire which is resistant to oil, gas, heat and rot. The main length of wire in the Racetronix harness is three to four gauges thicker than factory wire which helps reduce resistive power loss to almost non-existent levels. This helps improve pump performance by as much as another 10-20%. High-quality weatherproof fuse holders and relays are used for maximum reliability. The Racetronix harness has factory-type connectors which plug directly into your fuel pump module/sender so no cutting or splicing is required. The Racetronix harness has a redundant ground upgrade as it is necessary to improve the harness on the negative side of the pump's supply as well.

There is nothing worse than being in the middle of an installation only to find that the manufacturer has skimped on installation hardware. This is why Racetronix supplies a spare ATM fuse, 25 black nylon wire ties, silicon grease and stainless mounting hardware with each kit.

Racetronix harnesses are considered the best by which all others are judged. Attention to detail in every Racetronix harness is evident at first glance. Racetronix spares no expense to ensure reliability, ease of installation and performance. All Racetronix harnesses are assembled using our computerized crimp-quality monitoring system and then circuit checked for the utmost in reliability. This harness is covered under our limited lifetime warranty.

UPGRADE OPTIONS

BGK

An optional battery to body

ground upgrade kit is available (P/N BGK8). This kit upgrades the under-rated

factory ground wire running from the battery to chassis. It includes a flexible 8 gauge copper wire and battery

nuts with accessory taps. We highly recommend this inexpensive option because

this is a weak point in these cars.

PBIC

The Racetronix harness comes

equipped with an interface connector just after the relay (see

product picture above). This connector in combination with an optionally

supplied connector set allows for easy plug and play addition

of a pump booster / voltage amplifier such as the MSD or KB units. These voltage amplifiers / boosters will allow the Racetronix single in-tank pump system to support an additional 100-200 flywheel HP (B.S.F.C. dependant) when run at 16-17 volts. This configuration

offloads the excessive current draw placed on the factory wiring onto the

heavy gauge Racetronix harness system. System diagnosis becomes easier

by simply being able to unplug, isolate and bypass sections of the wiring

system.